- Home

- About us

- Products

- Spot welding machine

- AC butt welding machine

- Flash butt welding machine

- Capacitive discharge welding machine

- Medium frequency welding machine

- Seam welding machine

- Rectifier DC welding machine

- DC inverter Welding Machine

- Row welding machine

- Customized welding machine

- Robotic cells

- Steel wire mesh production line

- Sink production line

- Steel wire products machinery

- Faqs

- News

- Certificate

- Contact us

Automobile shock absorber medium frequency projection welding machine

- FOB Price

US $1.001 - 2 piece

- group name

- Medium frequency welding machine

- Min Order

- 1 piece

- brand name

- CONNUC

- model

- SMCD-250

- Nearest port for product export

- Guangzhou, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union, Cash

- update time

- Wed, 24 Aug 2016 18:04:52 GMT

Paramtents

Voltage 3 phase, AC 380V, 50/60Hz

Rated capacity 300KVA

Duty cycle 50%

Inverter output frequency 1000Hz

Max short circuit current 80000A

Secondary voltage 11.6V

Welding arm length 500mm

Welding pressure 6800N, adjustable

Air cylinder working distance 60mm

Cooling water ≥12L/Min

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

The medium frequency inverter spot welding machine is customized welding machine for automobile shock absorber ring welding, above published is machine's technical specification.

CONNUC medium frequency inverter welding machine overview:

It is advanced welding quipment with core componnets includinginverter, welding controller, middle frequency transformer. It uses module design, uses imported electronic elements and equipped with micro-computer multi function controller. The controller uses 8-bit micro computer as heart,together with 2 groups analog/digital conversion circuit, so it canautomatially control power voltage changement & surrounding temperature change to ensure stable output, so to reach the best welding quality.

The machine has three momorizing function, easy setting and operation,suprior quality, very small fault, with reliable long term working.

The machine has small measurement transformer but with big output engery, it can increase the electricity networks’ 50/60hz to 1000Hz, maximumly reduced the steel core weight, Also the rectifier diodes in the secondary circuit can switch power to DC for welding machine, so it greatly improved the secondary loo inductance value which lead to engery lossing, so it reduces production cost to minimum.

Characteristics:

1. DC welding current, when secondary windnigs have inductive/magnetic material it will not affect the welding.

2. Make the power supply device with balance loading, the intermediate frequency inverter welding machine uses 3 phase power supply but with strong adaptability for power grid voltage fluctuation and voltage step down.

3. More precise & faster current controlling, more numbers & more accurate analysis parameters compared with power frequency system.

4. Faster reaching to setting current, 20 times faster than conventional technology.

5. More reliable process, majority of resistance welding metals will get better welding quality if by DC welding.

6. Cost saving,reduces every spot welding energy and shorts welding period.

7. Energy saving, especially very suitable for welding thick working piece and high conductive metals, such as aluminum & all galvanized steel sheet, copper wire & copper plate etc.,

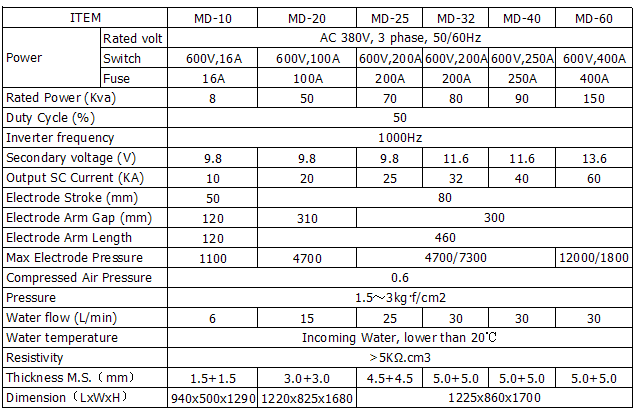

Technical specification:

* Technical datas are only for reference, specifications are subject to change without notice.

* Various special specification welding machine to be designed according to different shapes of workpiece.

* Customized order welcomed.

Our Competitions:

1. We are in resistance welding industry in China with over 20 years rich engineering experience; Factory direct sale, competitive price.

2. Customized Service: We can offer full engineer solutions from design, develop to produce the welding machine & its fixture according to your requirement.

3. Reliable welding machine with superior quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and CE standard. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here standing by for your demand.

5. Quick Delivery: Our company provides in-time delivery.

6. Prompt Response to Customers: Your satisfaction is our driving force.