- Home

- About us

- Products

- Spot welding machine

- AC butt welding machine

- Flash butt welding machine

- Capacitive discharge welding machine

- Medium frequency welding machine

- Seam welding machine

- Rectifier DC welding machine

- DC inverter Welding Machine

- Row welding machine

- Customized welding machine

- Robotic cells

- Steel wire mesh production line

- Sink production line

- Steel wire products machinery

- Faqs

- News

- Certificate

- Contact us

MF-80 High quality and high speed automatic steel drum seam welding and production line

- FOB Price

US $1.001 - 2 piece

- group name

- Customized welding machine

- Min Order

- 1 piece

- brand name

- CONNUC

- model

- MF-80

- Nearest port for product export

- Guangzhou, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union, Cash

- update time

- Wed, 24 Aug 2016 17:42:54 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

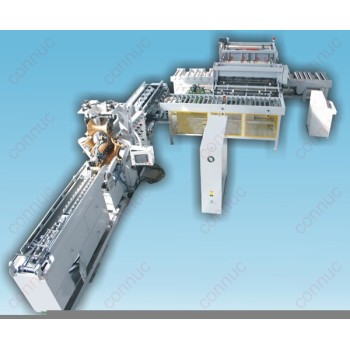

MF-80 high speed steel drum seam welding machine & production line

Three-phase middle frequency inverter (DC) automatic high speed steel drum seam welding machine

1. Product Description:

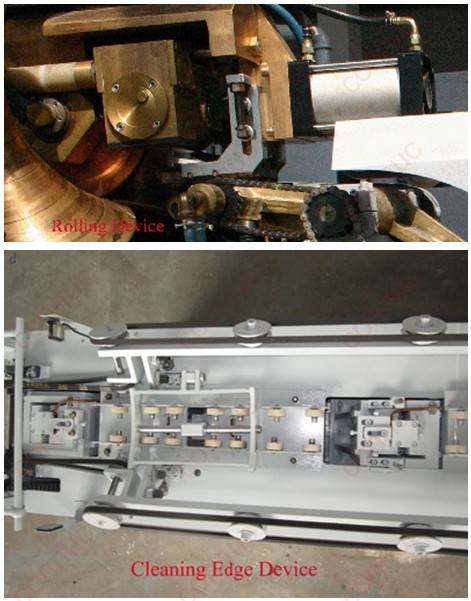

The machine adopts the international advanced middle frequency (1000 Hz) inverter DC power, welding method is rolling seam welding, electrode is cylindrical surface rolling wheel.

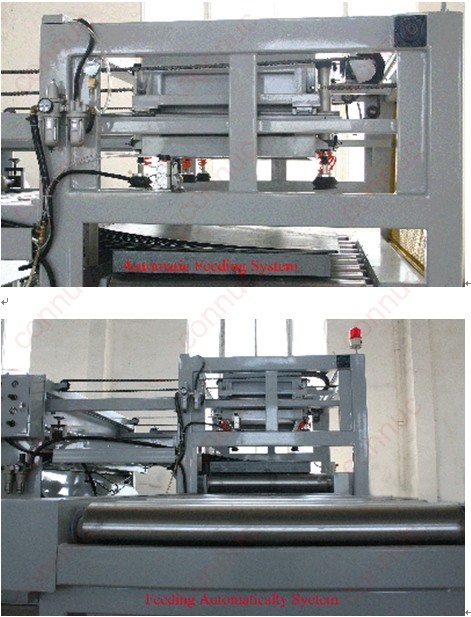

The steel drum production line integrates:

- vacuum cups conveying - automatic feeding

- rolling steel sheet to round drum shape

- spot welding

- rolling seam welding

- automatic edge trimming

- Automatic unloading

Material thickness range: 0.6 to 1.5mm

Rated power: 135KVA (MFDC 1000Hz) 380V

Compressed air pressure: 0.6mPa

Welding speed: 16m/min

Maximum production rate: 720pcs/hour

Drum diameter range: φ500~φ571.5 mm

Drum length range: 900~1025 mm

Cooling water :120 L/min 0.3Mpa ≤23℃±2℃

Steel sheet precision: Length ±0.5 mm /diagonal line±1.0 mm

3. Production Process:

Delivering the steel sheet to rolling area --- Rolled into the round automatically---The round drum transported for welding—Into welding place ---Welding ---Cutting edge---Discharging drum—Next circulation

4. Main components:

Logic controller, MITSUBISH (Japan)

Touch screen, MITSUBISH(Japan)

Transformer (Silicone steel from Japan), HORSE (Juntengfa)

Electrical machine, DOLIN (Tai wan)

Transducer, MITSUBISH (Japan)

Welding controller, HORSE (Canada technology)

Pneumatic component, AIRTAC (Tai wan)

Electromagnetic valve, triplet,etc, MINDMAN(Tai wan)

Rectifying tube , ABB(Germany)

IGBT , SEMIKRON(Germany)

Capacitor , FACON(Italy)

5. Production line photos: