- Home

- About us

- Products

- Spot welding machine

- AC butt welding machine

- Flash butt welding machine

- Capacitive discharge welding machine

- Medium frequency welding machine

- Seam welding machine

- Rectifier DC welding machine

- DC inverter Welding Machine

- Row welding machine

- Customized welding machine

- Robotic cells

- Steel wire mesh production line

- Sink production line

- Steel wire products machinery

- Faqs

- News

- Certificate

- Contact us

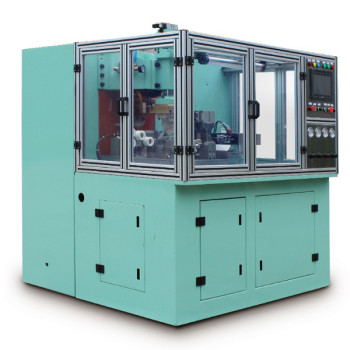

90KVA Medium Frequency DC Inverter Welding Machine for copper wire automatic welding & cutting

- FOB Price

US $5000.001 - 2 piece

- group name

- Medium frequency welding machine

- Min Order

- 1 piece

- brand name

- CONNUC

- model

- MD-40

- Nearest port for product export

- Guangzhou, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, Westem Union, Cash

- update time

- Fri, 08 Jul 2016 16:34:58 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Middle Frequency inverter welding machine overview:

It is advanced welding quipment with corecomponnets including inverter, welding controller, middle frequencytransformer. It uses module design, uses imported electronic elements andequipped with micro-computer multi function SL-MF110 controller. The controlleruses 8-bit microcomputer as heart, together with 2 groups analog/digitalconversion circuit, so it can automatially control power voltage changement& surrounding temperature change to ensure stable output, so to reach thebest welding quality.

The machine has three momorizing function,easy setting and operation, suprior quality, very small fault, with reliablelong term working.

The machine has small measurementtransformer but with big output engery, it can increase the electricitynetworks’ 50/60hz to 1000Hz, maximumly reduced the steel core weight, Also therectifier diodes in the secondary circuit can switch power to DC for weldingmachine, so it greatly improved the secondary loo inductance value which leadto engery lossing, so it reduces production cost to minimum.

Characteristics:

1. DC welding current, whensecondary windnigs have inductive/magnetic material it will not affect thewelding.

2. Make the power supply devicewith balance loading, the middle frequency inverter welding machine uses 3phase power supply but with strong adaptability for power grid voltagefluctuation and voltage step down.

3. More precise & fastercurrent controlling, more numbers & more accurate analysis parameterscompared with power frequency system.

4. Faster reaching to settingcurrent, 20 times faster than conventional technology.

5. More reliable process, majorityof resistance welding metals will get better welding quality if by DC welding.

6. Cost saving, reduces every spotwelding energy and shorts welding period.

7. Energy saving, especially verysuitable for welding thick working piece and high conductive metals, such asaluminum & all galvanized steel sheet.

Technical specifications:

ITEM | MD-10 | MD-20 | MD-25 | MD-32 | MD-40 | MD-60 | |

Power | Rated volt | AC 380V, 3 phase, 50/60Hz | |||||

Switch | 600V,16A | 600V,100A | 600V,200A | 600V,200A | 600V,250A | 600V,4000A | |

Fuse | 16A | 200A | 200A | 200A | 250A | 400A | |

Rated Power(kVA) | 8 | 50 | 70 | 80 | 90 | 150 | |

Duty Cycle(%) | 50 | ||||||

Output OC Voltage(V) | 7.9 | 11.9~13.9 | |||||

Output SC Current(KA) | 10 | 20 | 25 | 32 | 40 | ||

Electrode Stroke(mm) | 50 | 80 | |||||

Electrode Arm Gap(mm) | 120 | 310 | 300 | ||||

Electrode Arm Length(mm) | 120 | 460 | |||||

Max Electrode Pressure(N) | 1100 | 4700 | 4700/7300 | ||||

Compressed Air Pressure(MPa) | 0.6 | ||||||

Pressure | 1.5~3kg·f/cm2 | ||||||

Flow (L/min) | 6 | 15 | 25 | 30 | 30 | 30 | |

Temperature(0C) | Incoming Water, lower than 20℃ | ||||||

Resistivity | >5 | ||||||

(KΩ.cm3) | |||||||

Thickness M.S.(mm) | 1.5+1.5 | 3.0+3.0 | 4.5+4.5 | 5.0+5.0 | 5.0+5.0 | 5.0+5.0 | |

Dimension(LxWxH)(mm) | 940x500x1290 | 1220x825x1680 | 1225x860x1700 | ||||